There is more to an EX-inspection than completing a check sheet!

Without the underlying skills, knowledge, and ability to interpret standards and then document compliance - an inspection just literally becomes a box-ticking exercise!

Before an inspection takes place, we need to know the area's characteristics.

- Zone (and extents)

- Gas (or dust) group

- Temperature class

- As well as the often-disregarded Ambient temperature range

We should also know what environmental conditions will be present during operations (or cleaning) to determine whether the appropriate IP rating applicable for the area (again an often-disregarded characteristic).

In addition, we need to understand the equipment manufacturers’ intent.

We would hope details are contained within their Operations & Maintenance Manual as well as a Specific condition for use (if the certificate number has the suffix “X”) and a Descriptive system document for any intrinsically safe systems.

Here are 6 key points that would be considered as basic for an ‘EX’ inspection:

- KNOW WHAT ZONE YOU ARE INSPECTING

Gas Zones (0, 1, 2)

- Zone 0: Areas where explosive atmospheres are present continuously or for long periods.

- Zone 1: Areas where explosive atmospheres are likely to occur during normal operations.

- Zone 2: Areas where explosive atmospheres are not likely to occur but, if they do, will only persist for a short period.

Dust Zones (20, 21, 22)

- Zone 20: Areas where explosive atmospheres are present continuously or for long periods due to dust.

- Zone 21: Areas where explosive atmospheres are likely to occur occasionally during normal operations.

- Zone 22: Areas where explosive atmospheres are not likely to occur but, if they do, will only persist for a short period due to dust.

Unless you know what zone you are operating within you do not know if the installed equipment is suitable for compliant use! Click here for more info about area classification.

- UNDERSTAND AREA GAS/SUBGROUP:

- Group I (Methane) - Mines: This group includes gases and vapors that are likely to be present in mines.

- Group II (Surface Industries): Group II is further divided into three subgroups based on the ignition energy and the autoignition temperature of the gases and vapors:

- Group IIA: Includes gases with a high autoignition temperature and low risk.

- Group IIB: Includes gases with a moderate autoignition temperature and moderate risk.

- Group IIC: Includes gases with a low autoignition temperature and high risk.

For example, equipment designed for Group IIC would be suitable for environments with gases that have a higher risk of ignition, while equipment designed for Group IIA may be used in areas with gases that pose a lower risk.

Manufacturers, users, and inspectors need to be aware of the gas group classification when working with equipment in potentially explosive atmospheres to ensure safety and compliance with regulations.

Unless you know what Gas or Dust group you are operating within you do not know if the installed equipment is suitable for safe/compliant use!

- QUANTIFY TEMPERATURE CLASSES:

The temperature class is used to indicate the maximum surface temperature that a piece of electrical equipment can reach under normal or fault conditions. This classification is crucial for selecting and installing equipment in areas where potentially flammable gases, vapors, or dust may be present.

The temperature class is denoted by a number, which corresponds to a specific maximum surface temperature. The IEC temperature classes are:

T1: Maximum surface temperature not exceeding 450°C

T2: Maximum surface temperature not exceeding 300°C

T3: Maximum surface temperature not exceeding 200°C

T4: Maximum surface temperature not exceeding 135°C

T5: Maximum surface temperature not exceeding 100°C

T6: Maximum surface temperature not exceeding 85°C

Unless you know what Temperature class you are operating within you do not know if the installed equipment is suitable for safe/compliant use!

- COMPREHEND THE EFFECT OF AMBIENT TEMPERATURE;

By default, the standards for equipment ambient temperature is -20°C to +40°C, but often manufacturers will apply extended ratings for hot or cold environments.

For example, in the UK the ambient temperature is unlikely to exceed 40°C, and therefore standard ambient temperature should suffice - However in the UAE for example, the ambient temperature may exceed 40°C.

What does this mean?

Although not technically linear, an example could be that a T6 (85°C) piece of equipment certified for a standard ambient temperature of -20°C to +40°C, installed in an area where the ambient reaches +60°C, the maximum surface temperature could theoretically reach +105°C (becoming unsuitable for a T6 area).

Unless you know the maximum ambient temperature you are operating within you do not know if the installed equipment is suitable for safe/compliant use!

- UNDERSTAND IP RATINGS

The IP code was developed to rate and grade the resistance of enclosures of electric and electronic devices against the intrusion of dust and liquids and also defines the tests to be performed to verify that the enclosure meets these requirements.

The IP code is composed of two numerals:

The first numeral refers to the protection against solid objects and is rated on a scale from 0 (no protection) to 6 (no ingress of dust).

The second numeral rates the enclosure’s protection against liquids and uses a scale from 0 (no protection) to 9 (high-pressure hot water from different angles).

If the environment being worked in has NO/LOW dust or moisture levels a basic IP54 can be utilized however if the environment being worked in has HIGH dust or moisture levels more stringent protection is required as can be seen in the table below.

Unless you know what IP code suits the environment you are operating within you do not know if the installed equipment is suitable for safe/compliant use!

6. INFORMATION IS POWERAlways refer to:

- The manufacturer's Operations & Maintenance Manual or User manual – this is prepared by the manufacturer to provide important information regarding the safe installation, operation, and maintenance of certified equipment.

- The ATEX/IECEx equipment certificate – this is prepared by the certification body to show compliance with standards and directives and provide any specific conditions of installation or operations.

- The Descriptive system documents for any intrinsically safe systems – this should be prepared by the manufacturer/designer to prove the intrinsically safe parameters are within safe limits of use.

Unless you know the intended use and limits of equipment you do not know if the installed equipment is suitable for safe/compliant use!

7. SUMMARY

Ex inspections are driven by relevant standards and certification schemes.

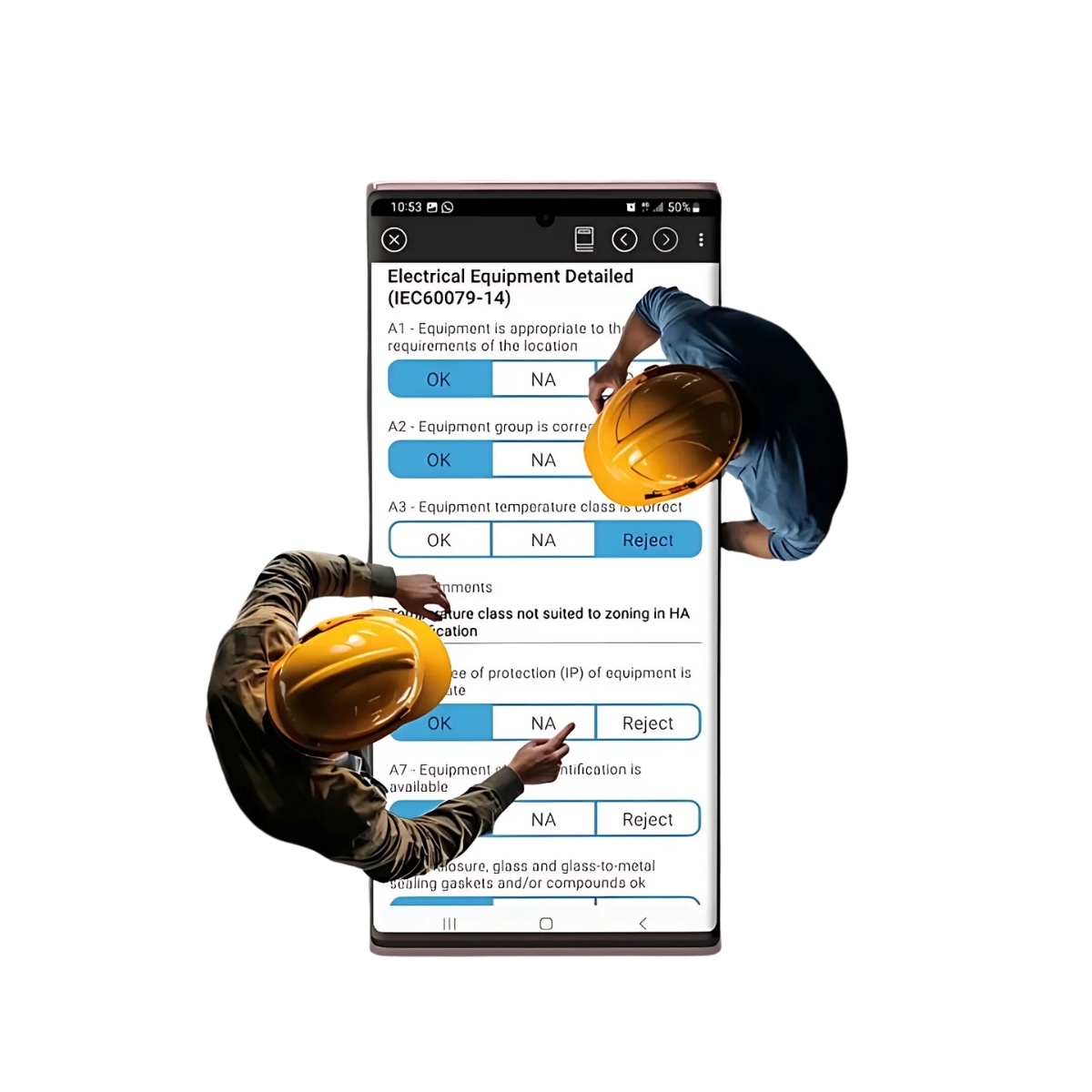

Many Industries follow the IEC 60079 series of standards and mandate the use of the IECEx certification scheme - These standards & schemes require ‘Ex’ equipment located in a hazardous area to be inspected before use (initial inspection) to ensure it is safe to energize in a hazardous area and that the Ex integrity has not been compromised during selection or installation.

Also, regular periodic inspections are mandated to ensure that the equipment has not been damaged and that its ‘Ex properties’ have not been compromised by corrosion, decay, wear and tear, etc.

ABOUT EUTEX INSPECTIONS

EUTEX sees an average 40% failure rate on new installations which mostly can be avoided by introducing specific checks by experienced competent persons - a conflict of interest is often seen if a manufacturer/supplier/installer is inspecting and certifying their own work therefore Inspectors should be different to Installers and be experienced practitioners with the appropriate competency Certification ( i.e.. IECEx CoPC or CompEx)

Use of an IECEx Accredited Inspection company that is well-established with a comprehensive successful track record is recommended – EUTEX is an IECEx-certified service facility for inspection see: https://www.iecex-certs.com/#/deliverables/CERT/1617866/view

.jpg)